NEWMILNS

LACE INDUSTRY

NEWMILNS LACE

Newmilns, a Royal Burgh from 1490, was a centre for Lace curtains and tablecloths and, in its heyday, over 2,000 people were employed in some twenty companies.

At the end of the 16th Century, handloom weaving was brought to the Irvine Valley by Flemish refugees who settled in the area. Around two centuries later, the Newmilns lace industry rose to national prominence, as Britain began importing cotton from the United States, Newmilns

already had a long-established weaving tradition. Nearer the end of the 19th century, handloom weaving was in decline with the introduction of the power loom in 1877 and in the 1880's the introduction of madras-making power-looms automated the process and left handweavers out of work. This technology is still relevant today.

After the United States introduced tariffs to protect their lace industry, new markets had to be found and by 1907 the lace industry bounced back. The industry became the largest employer in the area and Newmilns enjoyed a period of growth. Lace and madras weaving continued to flourish until the late 1970's, but the struggle for companies to compete with the distribution of emerging European and Asian economies had a profound effect on the Scottish textile industry.

Although the industry has diminished much in capacity over the last 50 years, there is still a world-wide demand for lace with

Morton Young and Borland and

Haddow Aird & Crerar now the last remaining lace factories in Newmilns.

Scottish Madras loom in MYB Textiles - Image circa 1970.

Manufactured by Andersons of Glasgow, this loom was used to produce Scottish Madras (originally called Leno Gauze Weave). The name Madras became a generic term as a result of the large amounts of cloth distributed to the city of Madras in India. MYB in Newmilns is the only place in the world still producing Madra, although now on more modern Vamatex looms. There are no old style Madras looms in existence.

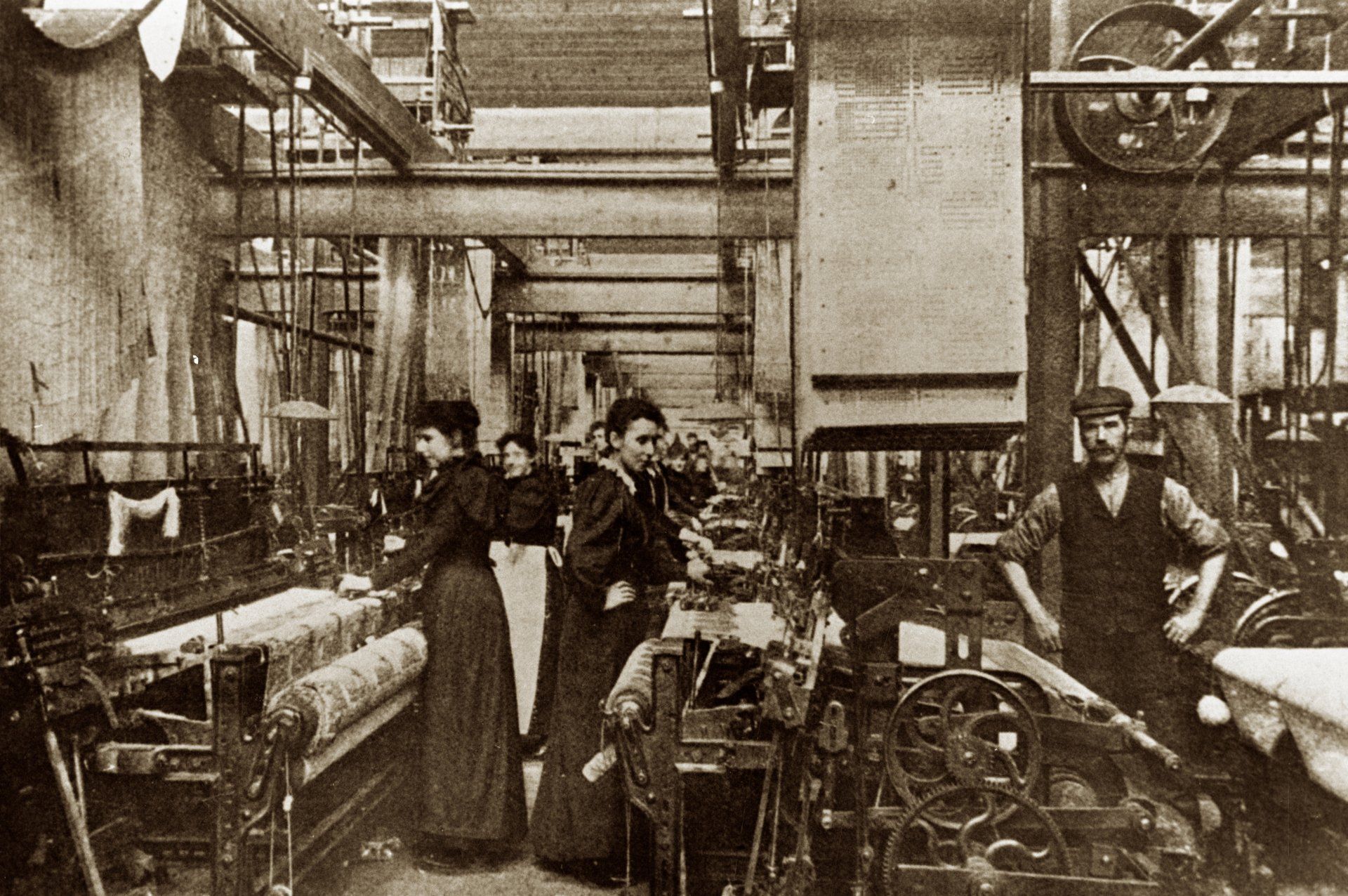

Madras loom workers - Image circa 1890

Women predominantly worked the smaller Madras looms, while men were responsible for the heavier manual work involved in the operation of the larger curtain lace machines. The gentleman on the right was a 'Tenter' and was in charge of setting up the cloth, the different types of weave, and any repairs. These looms were belt driven by a steam engine - the remnants of which can still be found in MYB Texiles in Newmilns.

Image courtesy of Irvine Valley Burns Monument Centre.

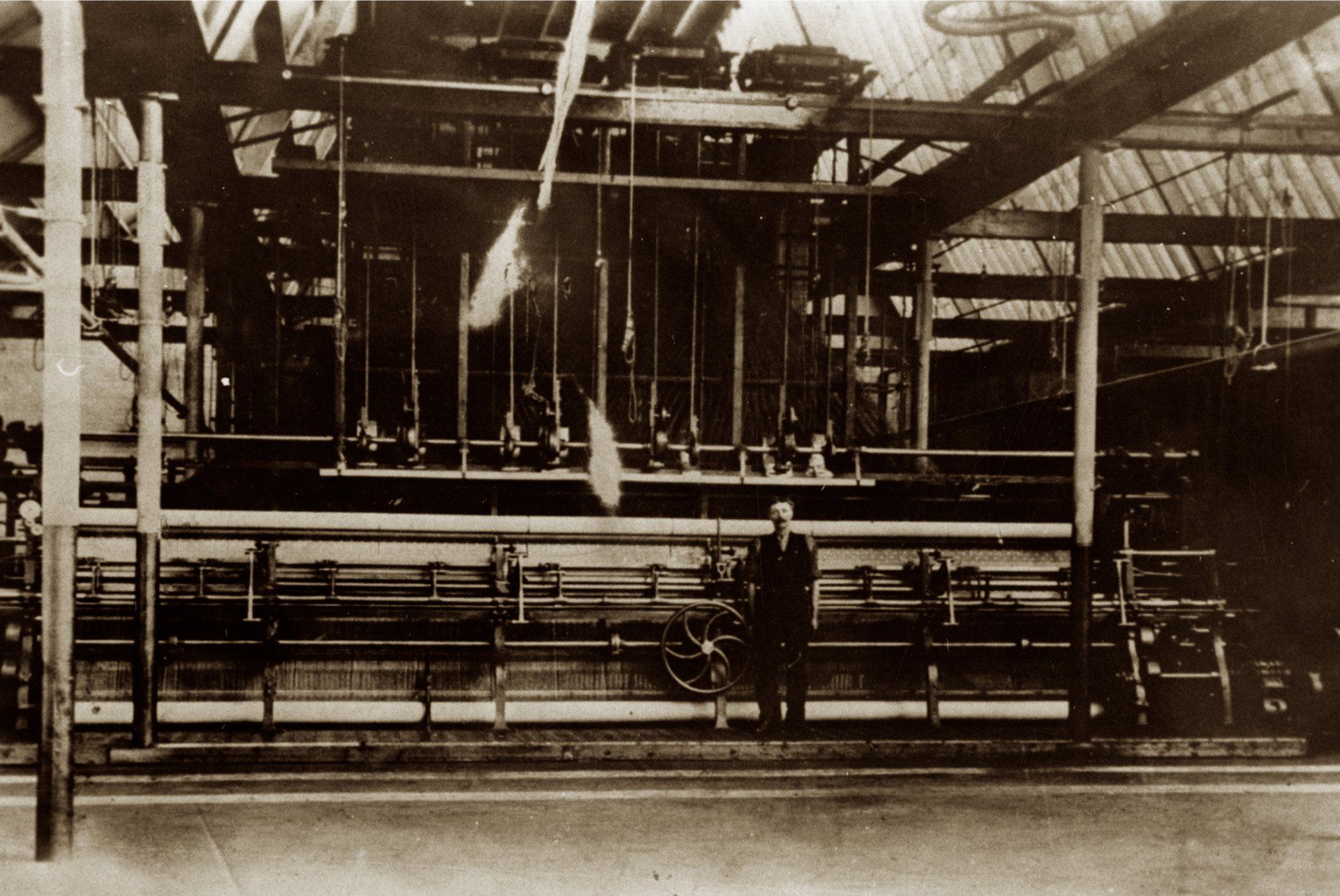

Machine No.5 at MYB Textiles

This curtain lace machine, built in 1913, can be found in MYB Textiles in Newmilns and is still in operation to this day, although it now uses digital technology rather than Jacquard pattern cards. The Irvine Valley produced more curtain lace than anywhere else in the world, and is the only place left where 100 per-cent cotton lace is produced.

Image courtesy of Irvine Valley Burns Monument Centre.

Grey Room hand darners

The 'grey room' is where the experienced hand darners mended the flaws when the 'grey state' lace first came off the machine. Once darned, the fabric was sent to finishers for stretching and dyeing and then was taken to the 'white room' for cutting anc packing. Hand darning is performed in the same way today - with a team of skilled women sitting on low stools.

Image courtesy of Irvine Valley Burns Monument Centre.

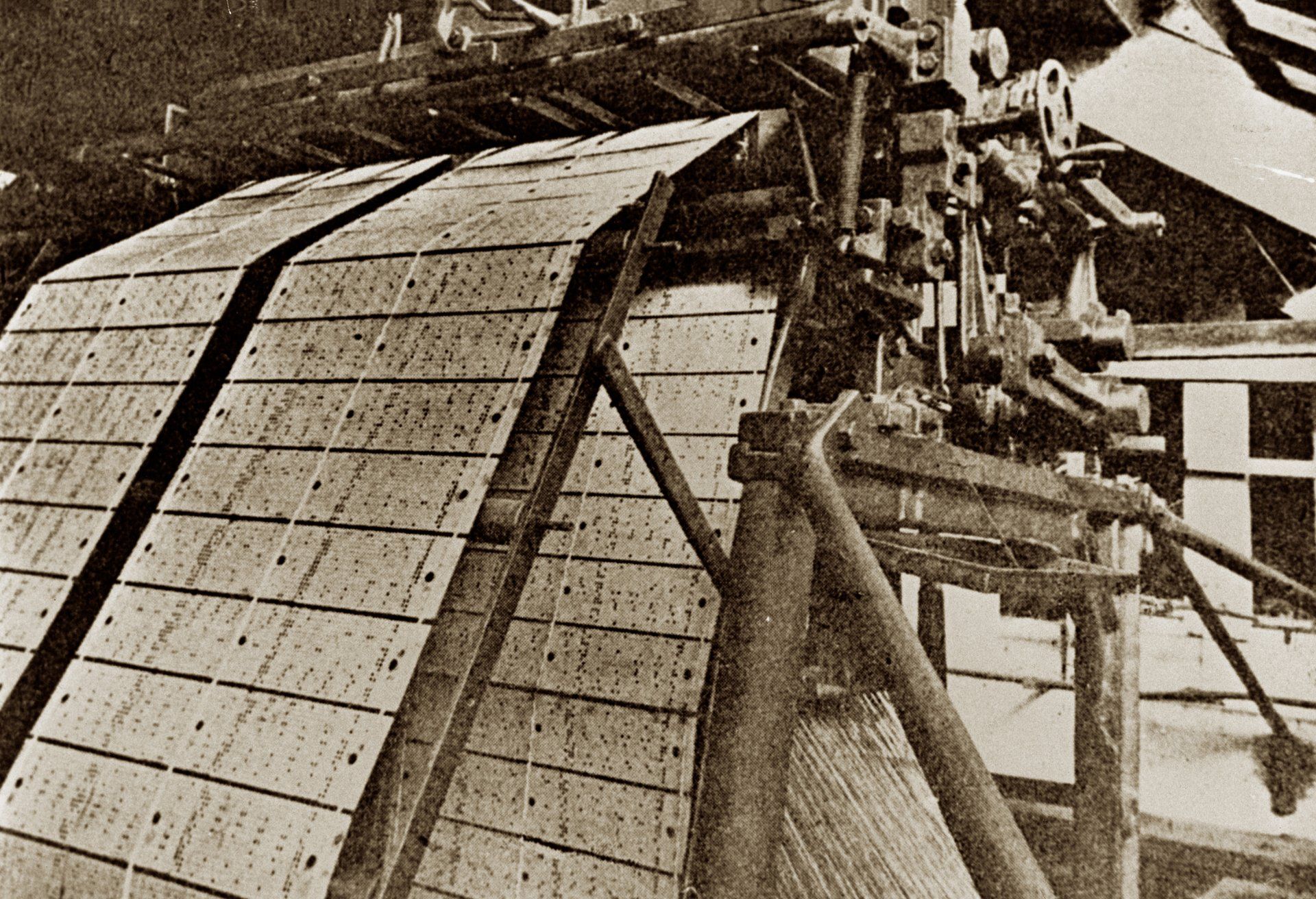

Rear view of a Jacquard machine.

Joseph Marie Jacquard created the programmable pattern - an invention which forever changed the weaving industry and inspired the technology of punch cards. This was the first practical use of the binary system which, in turn, led to the development of the computer. The designs are stored on a series of cards which are joined to form a continuous chain. Complex lace patterns can require tens of thousands of cards and are still used to this day,

Image courtesy of Irvine Valley Burns Monument Centre.

View of the mills - circa 1890

Alexander Morton first introduced mechanised lace furnishing machines to the Irvine Valley in 1875, leaving many of the burgh's traditional hand weavers unemployed. However, within ten years Morton's success led to a boom in the lace manufacturing, providing work for up to 6,000 people.

Left to right: Forrest & Gillies Bleachworks, R&A Muir 'Caledonia Mill', A&J Muir 'Annabank Milll', Johnstone & Shields 'Vale Lace Works'.

Image courtesy of Irvine Valley Burns Monument Centre.

Riverbank Mill, Newmilns - image circa 1966

2 Stoneygate Road, Newmilnsm originally Goldie, Steel and Company. By the end of the Second World War, there were 14 lace and Madras factories in the Irvine Valley. Today, only two remain.

MAILING LIST

Keep up-to-date with the latest from Newmilns Regeneration Association.

Contact Us

Thank you for subscribing to our newsletter. You can unsubsribe at any point using the Unsubscribe option on any Newsletter you receive or by emailing UNSUBSCRIBE to hello@lovenewmilns.org

Please try again later

Newmilns Regeneration Association promote the prevention or relief of poverty, and work towards the advancement of community development. We advance arts, heritage and culture; promote the provision of recreational faciltiies and organise recreational activities for the benefit of the people of Newmilns and Greenholm